In this post, we will share two internal combustion engines; they are the most common in the market.

A two stroke engine also called two-cycle engine means one stroke in each direction. It can complete a power cycle in only one crankshaft revolution and with two strokes. On the return stroke new fuel mixture is inserted into the cylinder. Here, “Stroke” refers to the movement of the piston in the engine.

Compared to two-stroke engines, the four-cycle engine has one compression stroke and one exhaust stoke. It uses the piston completes four separate strokes—intake, compression, power, and exhaust. The compression stroke compresses the fuel air mixture prior to the gas explosion. The exhaust stroke simply pushes the burnt gases out the exhaust.

How they work?

Two- stroke engine is simple as it has no valve, fuel and air in the cylinder have been compressed, and when the spark plug fires the mixture ignites. The resulting explosion drives the piston downward.

For four-stroke engines, piston travels down the cylinder while the intake valve is opened to allow a mixture of fuel and air to enter the combustion chamber. This process is called intake. Then the piston travels back up the cylinder thereby compressing the gasses after intake valve closed. After compressing, the spark plug ignites, and forces the piston down. The last cycle is the exhaust valve is opened, and then the piston will clear the chamber to start the process over.

Each time the piston rises and falls it turns the crankshaft that is responsible for turning the wheels. This is how fuel is converted into forward motion.

Main Differences (Are Two-Stroke Engines Better than Four-Stroke Engines?)

1. The two stroke engine only fires 1 time in each revolution whereas four stroke fires 1 time in 2 revolutions.

2. Two stroke comes with a light-weight body and simple design (has no valve, the piston act like a valve to control the flow of fuel), thus, it is less expensive to manufacture. But the four stoke is more versatile.

3. Four-stroke engine has a much higher efficiency than the two-stroke

4. Four-stroke engine is lower fuel consumption

5. Application

Two stroke engines are used for lower-power applications (dirt bikes, mopeds, jet skis, small outboard motors, as well as radio-controlled model planes) while four strokes are using in heavy duty, like automotive industrial, cars, trucks, and generators.

6. Two-stroke engines often provide high power-to-weight ratio and have a greatly reduced number of moving parts.

7. Two-stroke engines can work in any orientation, which can be important in something like a chainsaw.

|

|

Related product:

- GF26i 26cc Gasoline Engine 2 Stroke RC Airplane Engine CRRCPRO

- GF26i V2 Engine 26cc 2 Stroke Gasoline Engine for RC Airplane

- GP26R 26cc Engine Piston Two Stroke Petrol/Gasoline Engine for Airplane CRRC

- GF50i 50cc Engine Motor Two Stroke Airplane Gasoline Petrol Engine CRRC

- CCRC-Pro GF40i 40cc Petrol Engine Kit Two Stroke Gasoline Engine for Airplane

You can find more two stroke RC airplane gas engines on mbuynow.com.

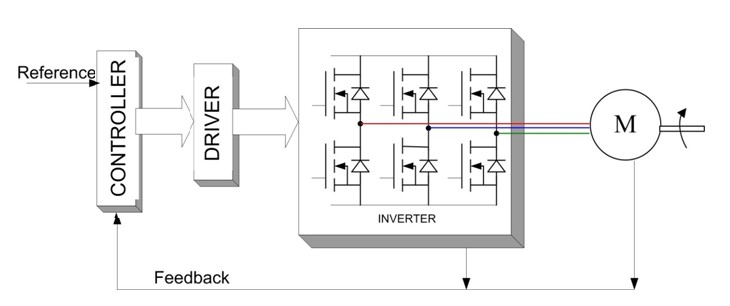

brushed DC electric motor

brushed DC electric motor