Today, we’d like to share you with the differences of AC motor and DC motor as they are the most common in our life.

The same

Both motors work by basically positive and negative current chasing itself in a circle which never catches up to itself so the motors turn, and then converting electrical energy into mechanical energy.

Differences

If you’re familiar with AC and DC motor, you may find that their power, construct and control are different.

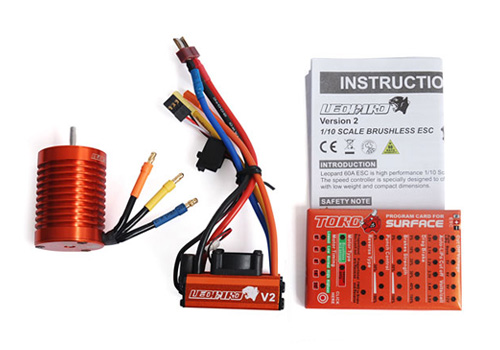

brushed DC electric motor

brushed DC electric motor

AC or alternating current motors are powered from alternating current while DC or direct current motors are powered from direct current, such as batteries, D.C. power supplies or an AC-to-DC power converter. The DC motor includes a brushes and a commutator while AC induction motors do not use brushes. For the difference of speed control, DC motor is controlled by varying the armature winding’s current while the speed of an A.C. motor is controlled by varying the frequency.

Advantages and disadvantages

Efficient

AC brushless motor is more efficient than DC motor. In AC, polyphase or three phase motors this becomes more efficient because you need lower current to do the same thing a DC motor does which requires more voltage to push it. Thus, AC motors are better suited for high speed operation (over 2500 rpm) since there are no brushes, and commutation is not a problem.

Speed control

DC motors with a better speed control than AC. Thus, DC motors are often use in rock crushers, car crushers, etc. A lot of your home appliances ironically run on DC motors too. In additional, there are various methods to control the speed of a DC motor, such as field flux control, armature control method, and voltage control method.

Maintenance and life

AC motors require virtually no maintenance and are preferred for applications where the motor is mounted in an area not easily reached for servicing or replacement. So they are very rugged and have long life expectancies. On the contrary, DC motors need more maintenance, limit the speed and usually reduce the life expectancy.

Price

DC motors are easy to build as they are less complex with a single power conversion from AC to DC and very cost effective for most horsepower ratings.