Anyone can build your own brushless DC motors. Brushless DC electric motors are also named BLDC motors that are synchronous motors that are powered by a DC electric source via an integrated inverter/switching power supply. The controller of BLDC motor is easier to build and it has better torque characteristics than some other types.

Today, we will discuss how to build a simple brushless DC motor.

Structure

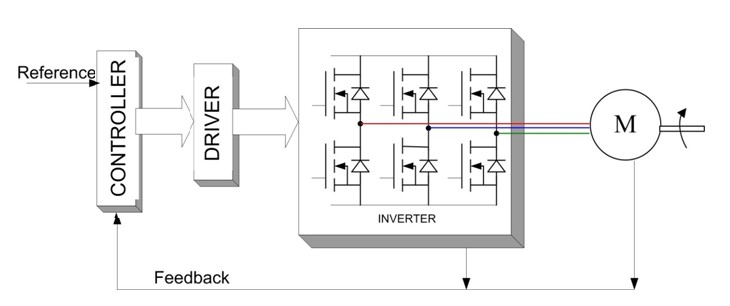

To build a motor right, you need to understand some basics of brushless DC motors. BLDC motor uses a rotating permanent magnet in the rotor, and stationary electrical current/coil magnets on the motor housing for the rotor, but the symmetrical opposite is also possible. A motor controller converts DC to AC.

How does a BLDC motor works?

Unlike brush DC Motor counterparts, the Brushless DC Motor does not contain any carbon brushes. Instead, the electromagnets within the motor remain stationary along with the armature, while the encased permanent magnets rotate, generating torque. The Brushless DC Motor is synchronous; both the stator and the magnetic field generate the same frequency, therefore avoiding any type of “slip” most induction motors exhibit.

Requirements

Laminations

Eddy current cause heat loose which essential take away from the possible output power of the motor. Typically professionally mode motors have laminations that are no more than half of a millimeter thick.

Magnets

Motors can be made using any type of magnet, either that be the less powerful ferrite magnets or the more powerful neodymium magnets. To meet this demand neodymium arc magnets where used with an N50 rating.

Windings

Get number of windings you want.

Wire

It was preferable to do a thicker gauge wire so more current could flow at the cost of less turns. A wire gauge size 23 with a fussing current rating of 35A, which is more than will ever be put through the motor, was used.

Summary

The motor took a very long time to design, and the biggest factors that limited the motor were cost and how the motor would be machined. Just building a brushless DC motor out of house hold things isn’t very practical. Usually, we would suggest you buying one already assembled.