Nowadays, AC motors have a far greater percentage of electric motors in service. However, the DC motor is of considerable industrial importance. The advantage of a DC motor is that its speed can be changed over a wide range by a variety of simple methods. Then, we may have a question: why we need to control the speed of a DC motor?

High power systems for RC model can be very dangerous; sometimes it may become a killer. The motor should only rotate in a rated speed; if the speed is more than rated speed then the motor will be damaged.

How to control the speed of a DC motor?

See more our post How to Choose the Right Speed Controller?

There are several of methods to control the motor speed, such as armature control method, field flux control and voltage control method. To control the speed of motor a rheostat should be connected to the field side of motor, by varying the rheostat we can control the speed of motor.

First, we may learn about how the DC motor works?

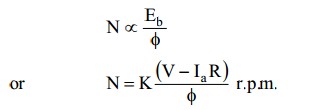

The speed of a DC motor is given by:

It is clear that there are three main methods of controlling the speed of a DC motor, namely:

(i) By varying the flux per pole (f). This is known as flux control method.

(ii) By varying the resistance in the armature circuit. This is known as armature control method.

(iii) By varying the applied voltage V. This is known as voltage control method.

Flux control method

In this method, the flux is reduced (and hence speed is increased) by decreasing the number of turns of the series field winding. With full turns of the field winding, the motor runs at normal speed and as the field turns are cut out; speeds higher than normal speed are achieved. This method is usually employed in the case of fan motors.

Armature-resistance control

There is a variable resistance directly connected in series with the supply to the complete motor which reduces the voltage available across the armature and hence the speed falls. By changing the value of variable resistance, any speed below the normal speed can be obtained.

Voltage control method

In this method, the voltage source supplying the field current is different from that which supplies the armature. Thus, this method avoids the disadvantages of poor speed regulation and low efficiency as in armature control method. However, it is quite expensive. Therefore, voltage control method is employed for large size motors where efficiency is of great importance.